1941 – 2022

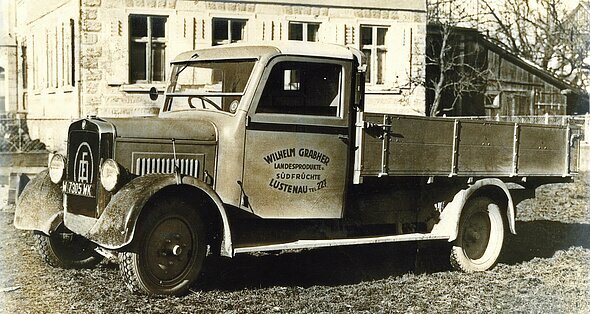

1941

Founding of the company Wilhelm Grabher & Co in Lustenau, Austria

The foundation for the Vorarlberg family business 11er Nahrungsmittel GmbH were laid by Wilhelm Grabher in 1941. Back in those days he founded a small mobile greengrocery business together with his brothers. Eventually the leading producer of potato specialities in Austria was to develop from the concept of supplying the surrounding villages with fresh vegetables. The pledge of quality was already a firm part of our company culture then and continues as such to the present day.

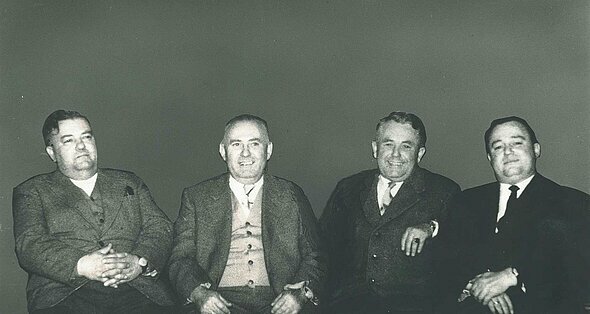

The Grabher brothers

In the beginning the four brothers, Rudolf, Wilhelm, Ludwig and Ernst Grabher (l. to r.) drove from village to village with horse and cart and traded primarily with fruit, potatoes and cabbage. Thus the brothers laid the foundations for the current family business 11er.

1968

The 11er sauerkraut factory

Everything didn't always revolve around the terrific tuber for the 11er. Before the potato specialities arrived 11er produced sauerkraut in its own factory. Later on in the face of increasing demand from foodservice French fries were also produced. Due to their great success these eventually replaced the sauerkraut completely.

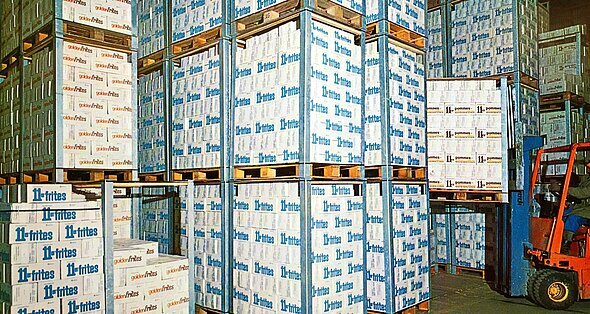

1971

French fries on course for success

The advent of the 1070s was the beginning of a new era at 11er: The first French fries were produced. As a result of their huge success the production of French fries was expanded within a few years.

1975

The first 11er cold store

It was not always as easy to store deep-frozen products as it is today. In contrast to the present day with its ultra-modern cold storage and refrigerated transportation things were significantly more complex at that time.

Back then 11er was already banking on innovation and cutting-edge technology and thus erected its first cold store in 1975.

1978 - 1979

11er enters the retail trade

It was only a matter of time before 11er French fries managed to make the leap from the restaurant onto the household plate.

At the end of the 1970s the tasty French fries were available from the supermarket for the first time.

1983

Foundations for environmental protection

At that time it was already an aspiration of the owners to do something for the environment and set their store by regenerative energy. Thus the first biogas plant was commissioned and an effluent treatment plant installed.

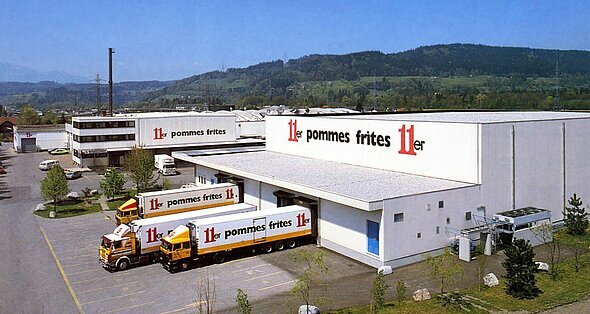

1986

Start of construction of the second 11er cold store

Needless to say as a result of the continuous growth in demand for 11er potato products it was also time to expand the storage facilities. With the construction of a second refrigerated warehouse as early as the mid-1980s 11er was already on the right track to becoming Austria's leading producer of potato specialities.

1988 – 1991

Making the most of the potato

Even at that time 11er was endeavouring to make the most of the potato. Hence with the establishment of the own speciality line in good time the foundations were laid for our current range of crispy Rösti and fine croquettes.

1993

Launch of a world first

With the introduction of an eco-system for edible oil at the start of the 1990s 11er created a world first. The new 11er-SENNA-ECO-SYSTEM functions as a dispensing unit - for oil only.

Being easy and convenient to operate it eliminated empty cans and their disposal. Thus one was able to take a further step along the path of environmental protection.

1994

The Potato Service Company (KSG)

With establishment of the KSG we provided the 11er farmers with their own advisory centre. The duties of our potato specialists include providing advice for our long-term contract farmers and supporting and assisting them in the cultivation and harvesting of quality potatoes.

At the company site in Heimstetten the staff tend to our very own 11er seed potatoes. Storage of our crop in our own storage facility has also been the responsibility of our potato service company since the mid-1990s.

2003

The 11er factory outlet

Those who don't necessarily want to go to the supermarket or wholesaler to purchase their crispy Rösti or French fries can obtain them directly from the 11er factory outlet since 2003. Here you can get our 11er products and a lot more ... a visit is well worthwhile!

2008

Energy saving through heat recovery

With the construction of a heat recovery plant we have taken another step closer to achieving our objective of environmental protection. For example it is possible to prepare 70,000 l of hot water using the heat from our production.

2014

11er in new look

Through a complete relaunch of the 11er packaging we have brought a breath of fresh air to the refrigerated point of sale!

2015

11er Climate Initiative

As a producer of frozen potato specialities, we depend on fertile soil, clean water and pure air, which is why we have always endeavoured to produce in as natural a way as possible. Since 2015, we have been actively engaged in climate protection and have since been building strongly on the pillars of avoiding and reducing CO2 emissions along our entire value chain. Carbon dioxide that we are unable to reduce and avoid has been offset by the purchase of climate protection certificates by the end of 2022. We look back on this with pride.

All current information on the 11 climate initiative is available here.

2016

Saving up to 5,500 tonnes of CO2 per year

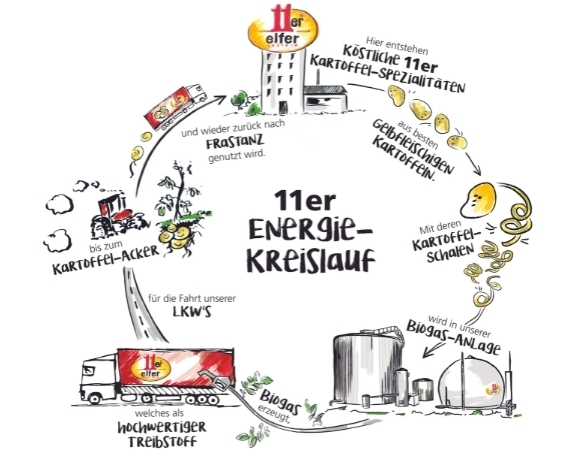

The ground-breaking in May marked the start of the construction of a new, higher-capacity biogas plant at 11er. The company has consequently been able to convert all such production waste as potato peelings into fuel-quality biogas on its own premises since autumn 2016. The completion of the new facility has allowed the company to usefully recycle all residual materials and reduce its carbon footprint by up to 5,500 tonnes of CO2 a year!

2016/17

The 11er energy cycle

The newly constructed biogas plant represented a milestone in progress towards CO2 neutrality and the energy recycling management. The residues from our production are converted into biomethane at the plant. We’ve already converted the first potato trucks to run on gas which allows us to utilise the methane we produce as fuel. These trucks travel several times a day to our potato warehouse and back again to Frastanz to deliver the fresh potatoes from which our potato specialities are made a short time later.

2017

The 11er GENUSS BUS Food Truck

Good cuisine and top-quality street food is what the 11er GENUSS-BUS aims to achieve. Everything revolves around our extraordinary 11er potato specialities. Our Food Truck Team cooks modern street food out of love for pure tasting pleasure: best ingredients from the region without unnecessary kitsch and with a dash of Austrian charm.

2018

The 11er Genuss Lädile Shop

The new 11er Genuss Lädile was opened in December 2018 directly next to the 11er factory in Frastanz, on the former site of the 11er factory sales outlet. The new design and the new shop concept mean that visitors can be inspired by the recent range that is full of regional delicacies and extraordinary 11er potato specialities.

2019

11er Genuss Bus wins European Streetfood Award for Austria

In May 2019, our 11er Genuss Bus team took the national title at the Austrian Streetfood Awards in Vienna and thus also qualified for the European Streetfood Contest in Malmö, Sweden. Also in Malmö our chef team could convince: Our signature dish, the extraordinary 11er Alpendöner with the delicious PimpYourFries, made 1st place in the category "Best Vegetarian".

2021

Deep-freezing with solar energy

Since April 2021, we have been using the sun to deep-freeze our golden-yellow 11 potato specialities. The PV system erected in April 2021 was expanded in October 2022.

On a total area of 9,200m², 2,518 PV panels were installed, which have an expected electricity yield of over 1,040,000 kWh. This electricity output could cover the annual electricity needs of 230 4-person households. The great added value: We at 11er need the energy exactly when the sun is most intense - during the day and in the warm spring and summer months. You can find more information about our climate protection initiative here.

2022

Construction of the deep-freeze warehouse IV

A new, state-of-the-art and fully automated high-bay warehouse was built on a total area of 2,000 m2 on the existing premises. It has a storage capacity of 8,000 pallet spaces. With the construction of this deep-freeze warehouse, 11er is committing itself to the current business location and gaining independence and flexibility for the future.

2024

Ten-Million Investment in Sustainability

With the second-largest investment in the company’s history, 11er is making a bold statement for the environment and the future: By late summer 2024, around ten million euros will have been invested in a modern air purification system, the energy-efficient use of residual heat, and the renewal of the flake press. This enables 11er to reduce natural gas consumption, improve air quality at the site and sustainably strengthen its own production base.

2025

New look, strong on the shelf – 11er Retail Redesign

Almost 10 years after the last redesign, 11er sets new accents in retail with fresh courage and a strong vision.

The new look combines alpine roots, modern elegance and a clear commitment to proven premium quality.