ENVIRONMENT

Responsibility for our environment

Climate change and extreme weather events are everywhere. The potato is a natural product, which is why we as a manufacturer of frozen potato specialities rely on fertile soils, clean water and pure air. To ensure this for future generations, it goes without saying that we are committed to sustainable environmental and climate protection measures, which is why we have been calculating our CO₂ emissions since 2013 and analysing where our emission drivers are and how we can reduce emissions. This forms the basis of the measures we have already taken and are planning.

WHAT WE HAVE ALREADY ACHIEVED

Reduction of carbon dioxide, savings and investments

Thanks to numerous measures, we have achieved a carbon dioxide reduction of over 40,000 tonnes over the last 20 years since 2004. Through continuous investment in environmental management, we have laid the foundations for further savings on the way to active climate protection. We have also been able to save large amounts of energy - around 200 million kWh in total since 2004. This corresponds to the average annual electricity consumption of 40,000 4-person households. The amount of energy used per kg of raw potato has also fallen. Today, we need around 41% less energy to process 1 kg of raw potato than we did in 2001.

Reduction & avoidance of CO2

We have been active for many years and will continue to use resources responsibly and as sparingly as possible in the future. We endeavour to reduce and, where possible, avoid CO₂ emissions along our value chain, particularly direct emissions at our Frastanz site and indirect emissions from purchased energy. Overall, we want to save 25% of our CO₂ emissions by the end of 2025.

FAQ

Frequently asked questions

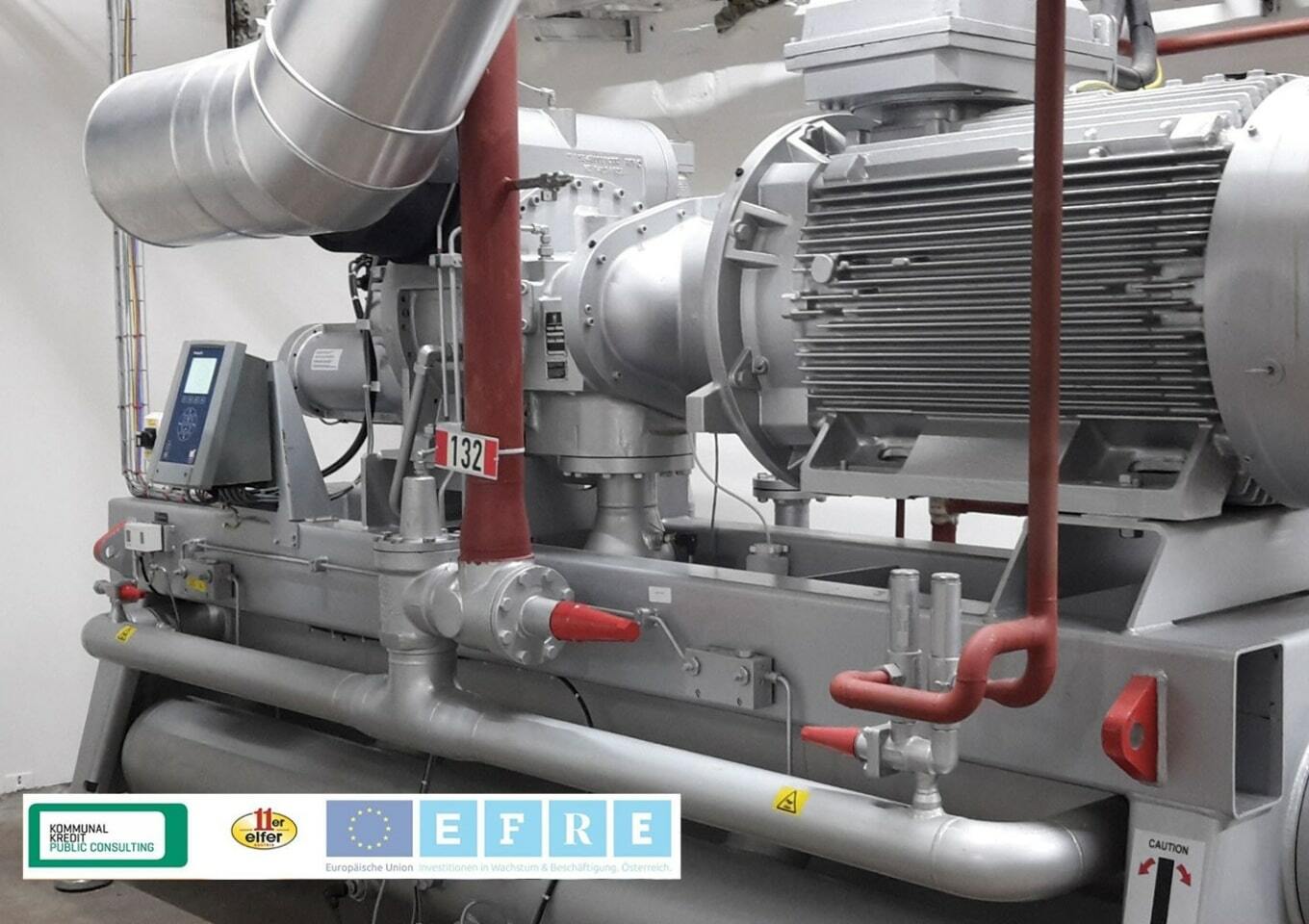

11er relies on electricity from renewable energies, uses heat recovery from waste heat, produces biogas from organic waste and continuously optimises energy efficiency in production.

11er sources its potatoes from Austria and southern Germany. Only yellow-fleshed potatoes from selected growing areas along the Danube and March rivers and from southern Bavaria are processed.

Sustainable packaging is an important part of 11er's environmental strategy. We rely on recyclable packaging and have already significantly reduced resource consumption over many years by reducing film thicknesses.

Organic waste from production is used in the company's own biogas plant and processed into biomethane. In this way, waste is utilised sensibly and converted into renewable energy.

11er uses electricity from renewable energy sources, operates its own photovoltaic systems and uses biogas to transport potatoes, among other things. In addition, waste heat from production is efficiently reused.